Refractory materials: ceramic composites, cermets and metal-based alloys

Coordinated by Massimo Emilio Angiolini, ENEA (IT)

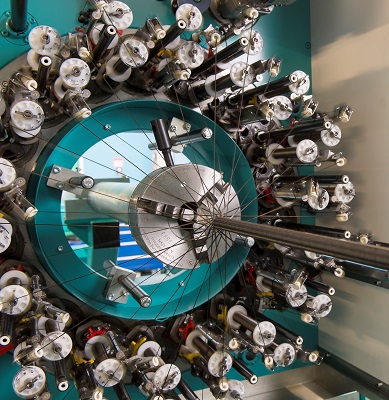

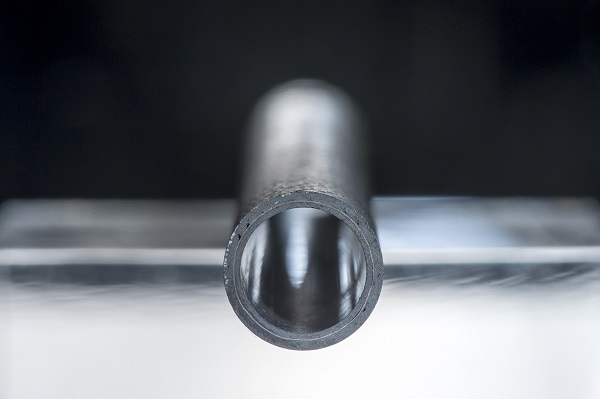

Ceramic composites (i.e. SiC/SiC made of nuclear constituents) are the first option for the fuel cladding of the gas-cooled fast reactor (GFR), with refractory alloys (i.e V-based) as a backup. This component will operate at temperatures above 900°C, exceeding the inherent capability of conventional and ODS steels. Pathway for a proof-of-concept study has been established addressing the manufacturability of representative clads from both materials; the integration of robust joining and coating technologies; the development of appropriate tools for basic characterization of key properties of safety concerns. However, most activities are currently de facto focused on SiC/SiC. Recently, emerging ternary carbide composites (i.e. MAX phase-based cermets) have been also included for preliminary evaluations as promising erosion/corrosion resistant materials for the liquid metal cooled systems. Seeking funding opportunities is integral part of sub-programme 3 strategy as well, to support the refractory clad technology development.